Plastic Injection Moulding

|

| |

Our plastic injection moulding facilities house a variety of injection machines across a wide range of tonnages. We invest in the best quality machines for optimum speed, energy, efficiency and versatility. Our capabilities include single colour injection machines, overmoulding and insert moulding

Our Core specialization is in the molding of High-Quality Precision Functional Parts with: |

| |

|

| Various type of engineering plastic |

|

|

| Hi-gloss appearance parts |

|

| |

| Precision functional parts |

|

|

|

| |

| Core-puller required parts |

|

|

|

|

|

| |

|

| |

|

|

Mould Design and Fabrication

|

| |

| Mould design and fabrication is an intricate work of art that lays the foundation for the entire production process. Our highly experienced team uses advanced Unigraphic CAD & CAM software, AutoCAD and Flow to create mould designs. By employing CNC milling, wire cut and EDM machinery, our team can deliver customized moulds of complex geometries and tight tolerances. |

| |

| We can manufacture: |

| |

|

|

|

|

| Small Mould - 10-ton small machine tool |

|

| |

| Medium Mould - up to 400-ton medium machine tool |

|

|

| Precision Mould - Tolerance 土 0.02 mm |

|

| |

| Thin Wall Mould - plastic thickness 0.35mm and above |

|

|

| Clear / Mirror surface Mould |

|

|

| |

|

CNC Machine

|

|

|

|

EDM Machine

|

|

|

|

Milling Machine

|

|

| |

|

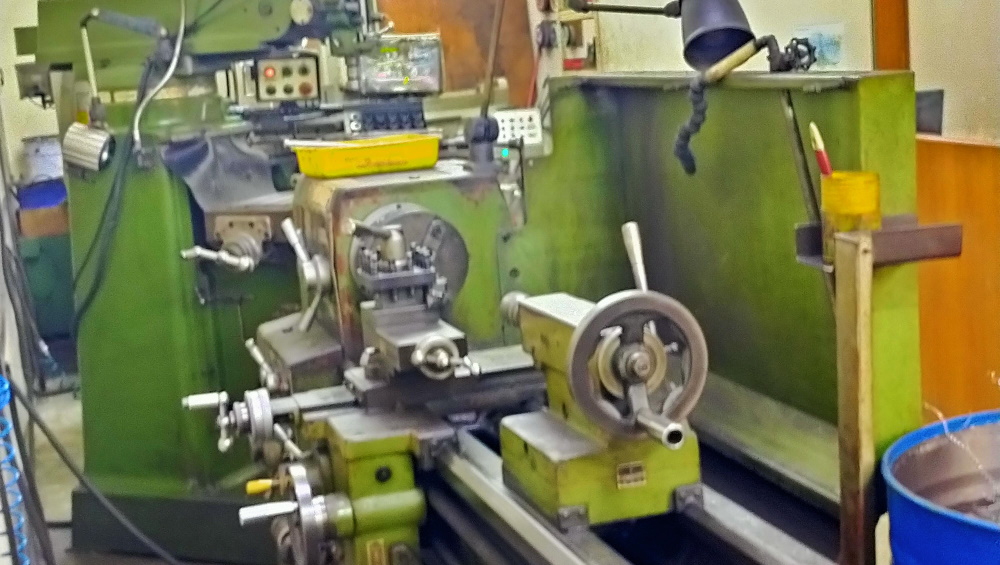

Lathe Machine

|

|

|

|

Grinding Machine

|

|

|

|

Ultrasonic Cleaning Machine

|

|

|

|

Metrology

|

| |

Our processing equipment maintains excellent accuracy and repeatability however it is important that we continually measure the parts that we mold to ensure that they meet customer specifications.

To ensure that we always meet the requirements of your specifications our quality departments are equipped with measure and test equipment that provides them with the ability to accurately and comprehensively check the components and assemblies that we produce.

We have tool and part validation processes to suit all applications. Starting from as simple as a few measurements and testing of fitment to mating components and finishing with Part Submission Warrant including, FA measurement, CpCpk Measurement, Production Part Approval Process (PPAP) |

| |

Measurement Tools

|

| |

|

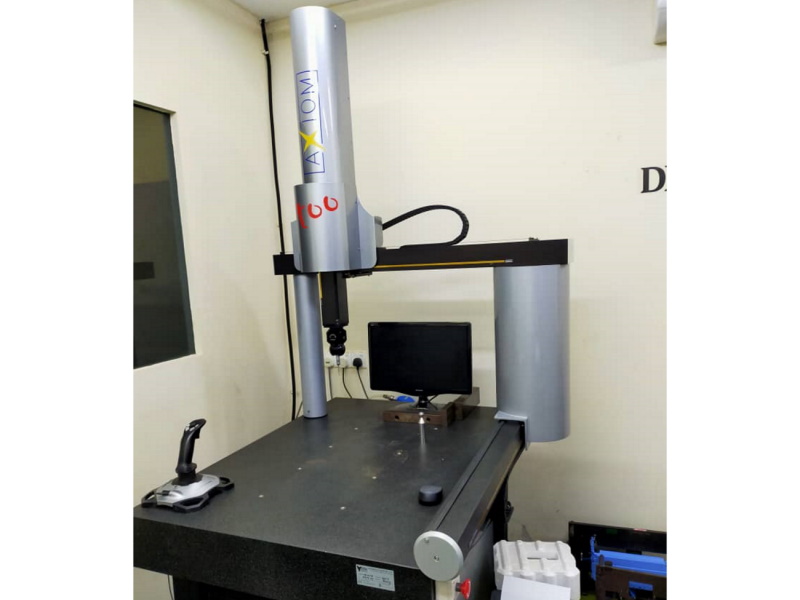

Fully Motorized CMM

|

|

|

|

Smartscope

|

|

|

|

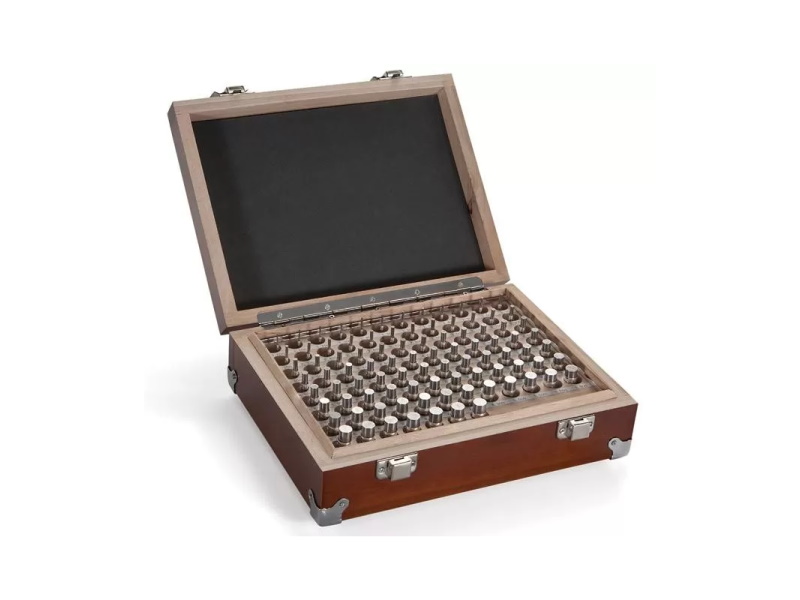

Pin Gauge

|

|

| |

|

Color Box

|

|

|

|

Vernier Caliper

|

|

|

|

Height Gauge

|

|

|

|

Product Finishing

|

| |

| Our customers benefit from the post moulding processes that we offer which include: |

| |

|

|

| |

|

Anest Iwata Spray Booth

|

|

|

.jpg) |

Auto Spray Spindle Line

|

|

|

|

Hot Foil Stamping

|

|

|

|

Pad/ Tampo Printing

|

|

|

|

Assembly

|

| |

| We provide assembly service to our valued customer with low to medium volume demand. The engineering team guides the project through every step of the machine building process, while meeting all documentation and validation requirements |

| |

|

|

|

Distribution & Warehouse

|

| |

Our warehouse has been designed with material flow as a major consideration. Raw materials are received, processed and moved into storage quickly and efficiently without interrupting the movement of finished

We can store and distribute finished goods where required. This service allows our customers to order finished goods to multiple delivery locations with confidence that our people and systems will always deliver the product to the right location at the right time. goods. |

| |

|

|

|